Assembly Assembly

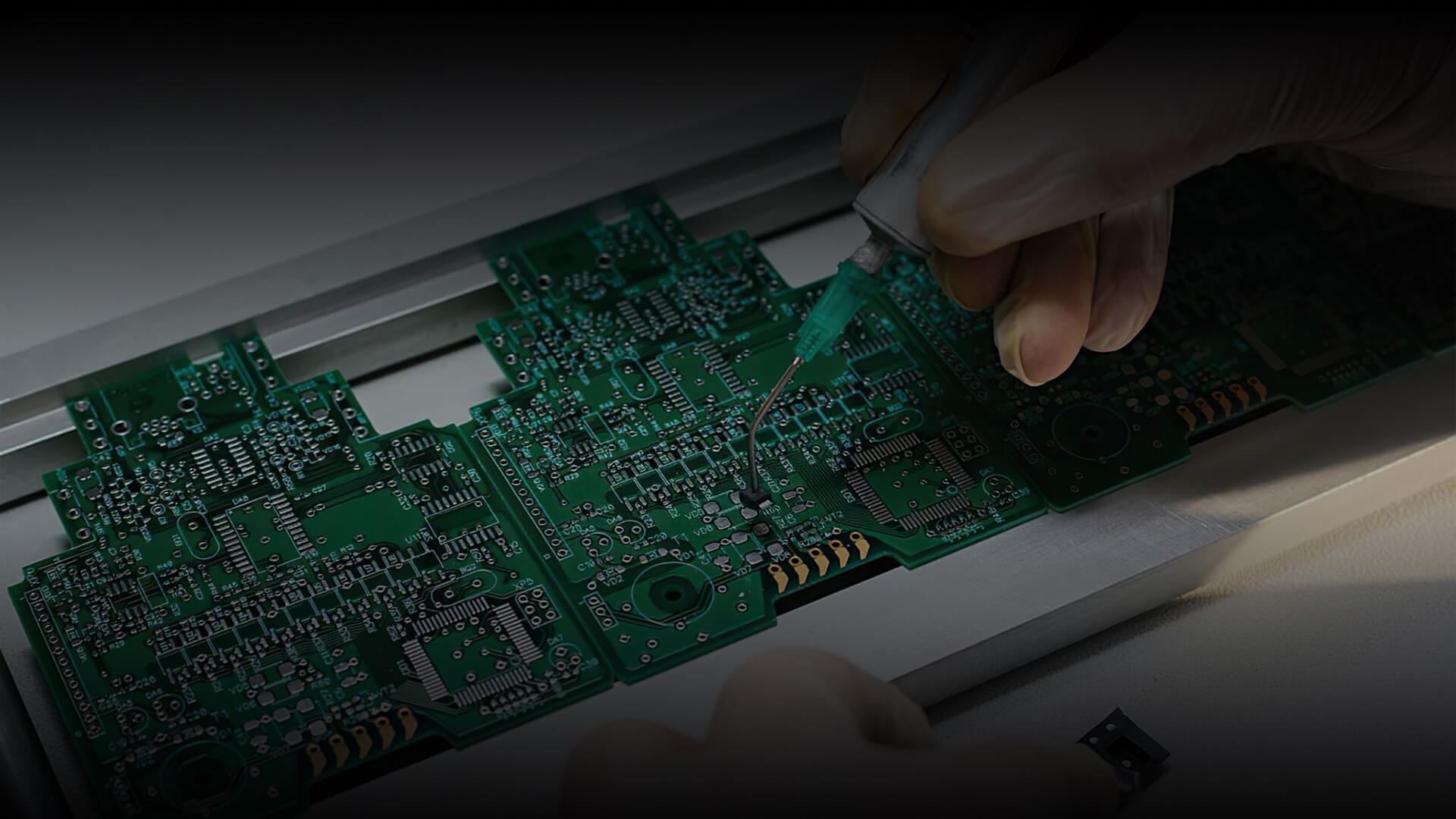

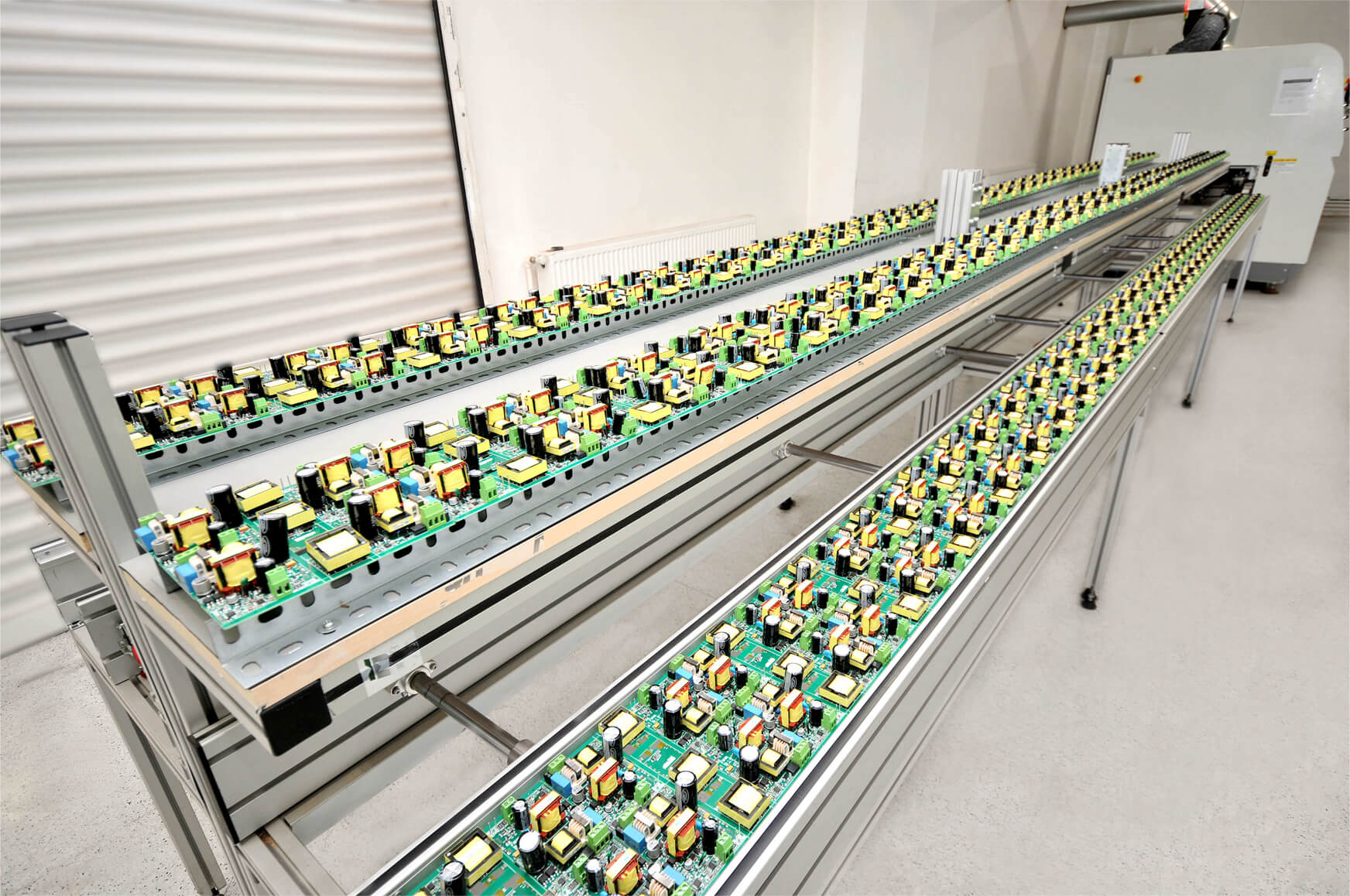

SMD Assembly Operations

In order to meet the electronic typesetting and other electronic needs of our customers, in 2018; We made the investment and processed our fast and reliable, fully automatic, high capacity and precision SMD line. In our SMD Assembly line, leaded and lead-free cream solder placement as well as bonding operations can be performed.

Our fully automatic printer machine performs the process of applying cream solder on the electronic card by using a specially produced stencil (screen) for each PCB. With our Pick and Place (P & amp; P) machines, we are able to arrange components on the PCB at appropriate coordinates , at the appropriate angle and height.