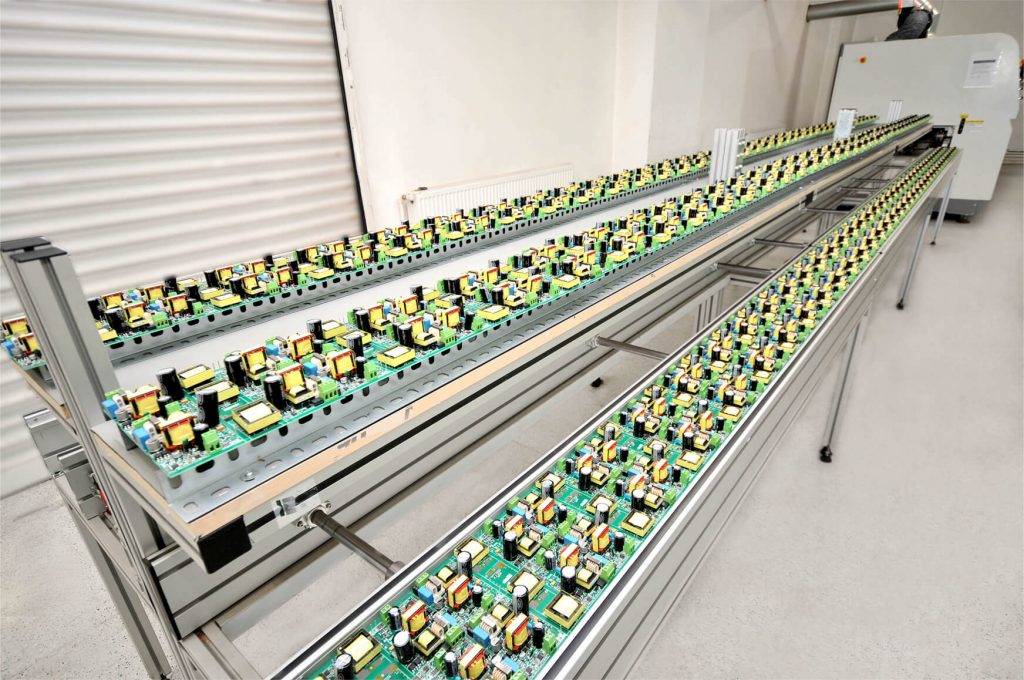

Pcb Loader

Conveyor

Solder Paste

Solder Paste

Reflow Soldering

PCB Loader

Loader units in our SMD lines ensure that the production is continuous and without intervention by sending the pcbs in the magazines on them to the SMD lines as needed. Unloader units prevent accumulation at the exit of the line by arranging the cards taken out after the furnace in magazines.

Solder Paste

In our fully automatic cream soldering machines, aligning with the camera, knife pressure control and under-sieve cleaning units are used to smooth solder cream. can be processed.

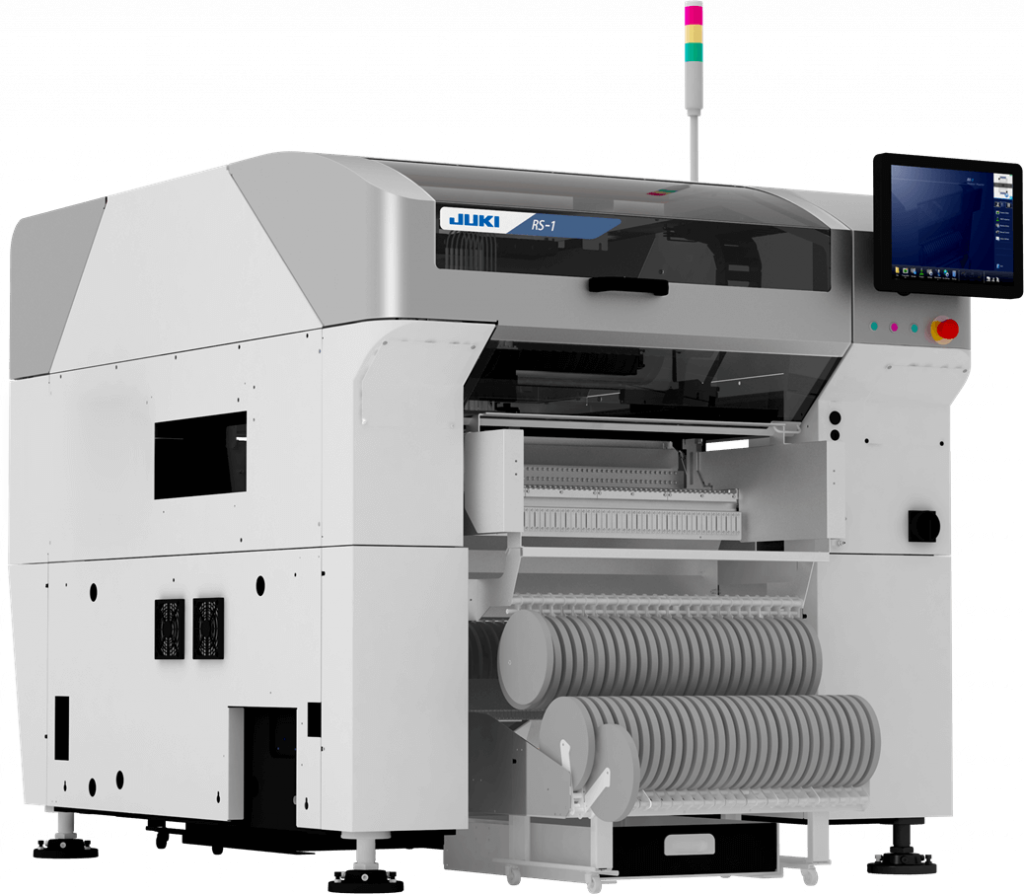

Solder Paste

Loader units in our SMD lines ensure that the production is continuous and without intervention by sending the pcbs in the magazines on them to the SMD lines as needed. Unloader units prevent accumulation at the exit of the line by arranging the cards taken out after the furnace in magazines.

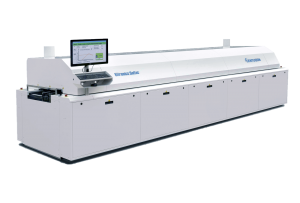

Reflow Soldering

Our convectional brazing furnaces have 8 bottom heating, 8 top heating and 2 cooling zones. With their support conveyor, they prevent post-oven distortions that occur in large cards. Healthy soldering is achieved in all materials on the board with the temperature profiles taken according to the production.

Masking is applied to the areas on the board that are not desired to be soldered. Components are prepared in cutting and bending machines to make them ready for stringing. Cards that are hand-assembled are passed through the wave soldering machine with leaded or lead-free solder, depending on the use. Materials that are not suitable for the wave soldering process are soldered by hand.

Control

Solder climbing, gravestone formations, direction and offset controls are performed very quickly and without error on the cards arranged after SMD assembly.

All situations on the card are checked by our experienced personnel after TH assembly and the cards are delivered smoothly.